Thermal Spray Aluminum

Thermal Spray Aluminum Coating or TSA Coating as an edge over traditional coating techniques on iron and steel works that provides total corrosion protection and improves life of the metal. Thermal Spraying of Aluminum or Aluminizing involves deposition of Aluminum of 99.5% purity over the prepared surface. The sprayed metal is melted by using Electric Arc that is atomized with compressed air and projected over the substrate, and is prepared using Sand & Copperslag Blasting.

This process is used to protect metal against corrosion and oxidation operating in high temperature environment like chimneys at cement plant, petrochemical industry, Oil & Gas Industry, boiler tubes metallizing as well as corrosive iron or steel at subsea & marine atmosphere.

Key Benifits

- Corrosion/ Rust Protection

- Energy savings

- radiation loss saving

- Less maintenance/Lowest long term cost

- Improved Durability

- Environmental Friendly

- Aesthetic Improvement

- Economic /Low Cost

- Ease of Inspection

- Applied in Field

- No Drying Time

- No Steel Restriction

- No Size Limitation

Process of Aluminum Thermal Spray

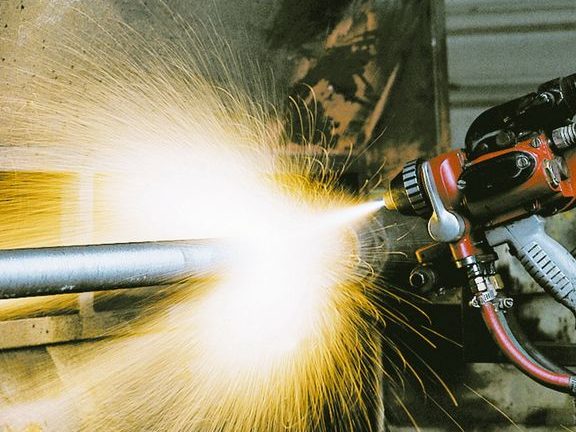

The metalizing process starts with preparing the surface of the product. Then a aluminum metal wire is melted in metalizing spray gun these molten metal is propelled on a coating surface by using atomized air to form the coating. A layer of HR sealant is applied over the coated surface for finishing and aesthetic look.

Surface cleaning

Sandblasting is process of roughing and cleaning a hard surface by forcing solid particles across that surface at high speeds using compressed air.

Thermal spraying

Thermal spraying is a process where metal or metal alloys are melted and then sprayed onto a prepared substrate, creating a thin layered coating of about 50-500 Microns.

Sealant application

Sealant application is a painting technique in which a device sprays coating material through the air onto a surface.