Thermal Spraying….

The term “Thermal spray” refers to a family of processes for which solids materials are decomposed into fine particles in a molten or semi-molten condition and accelerated in a gas stream, to form a coating on a substrate.

Metallizing

Metallizing is a process which involves depositing a thin metallic film on the surface of the metallic or non-metallic object.

Surface cleaning

Sandblasting is process of roughing and cleaning a hard surface by forcing solid particles across that surface at high speeds using compressed air.

Thermal spraying

Thermal spraying is a process where metal or metal alloys are melted and then sprayed onto a prepared substrate, creating a thin layered coating of about 50-500 Microns.

Sealant application

Sealant application is a painting technique in which a device sprays coating material through the air onto a surface.

Aluminizing

Aluminizing is a process where Aluminum or Aluminum alloys are melted and then sprayed onto a prepared substrate, creating a thin layer of metal coating.

Galvanizing

Galvanizing is a process where zinc or zinc alloys are melted and then sprayed onto a prepared substrate, creating a thin layer of metal coating.

SS Coating

This is also a type of wire arc thermal spray, where operating temperature are more than 600C This coating is also used for inside surfaces of chimneys where sulphur reaction takes place.

Our Focus…

As a metallizers, we need to protect metals from Rusting due to changing environment condition/Sevier working conditions.

None can Destroy Iron,

But its own Rust can.!!!

– Ratan Tata

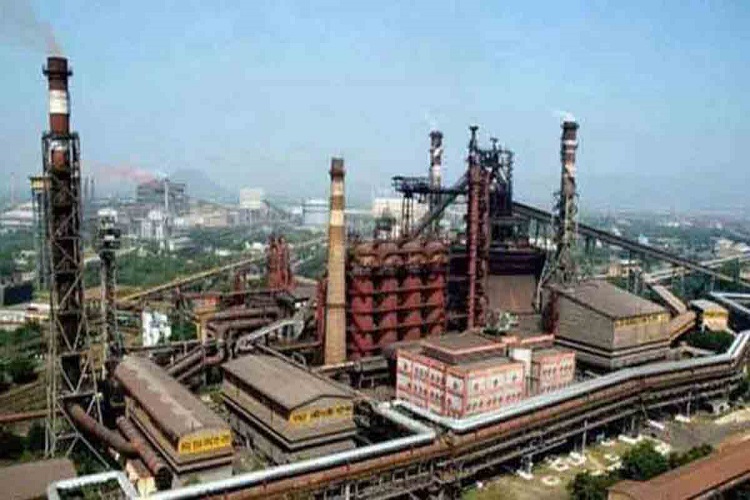

Aluminization for Preheater Towers…

Get Your investment back in just one year

Who doesn’t like a savings? Protect your plant by Metallization and get your investment in one year and also get 4 times more profit in the remaining warranty period.